New Air Spring product : ST-358-9970

2022-07-06

SENHO Will Attend the AAPEX 2022

2022-10-14Considering the white characteristics of the automobile system, the parts are an important part of the automobile system, which is of great significance to realizing the automobile’s function. If the quality of the parts is not good, the automobile’s safety will be directly endangered. Therefore, for automobile enterprises, selecting parts requires strict access standards. In this situation of strict control, auto parts enterprises must constantly improve quality management, strengthen quality control, and improve the effectiveness of quality management in order to effectively meet the needs of production and customer requirements from the market in the competition year to gain more market share. Therefore, we must pay enough attention to the quality management of auto parts and conscientiously do a good job in the quality management of auto parts enterprises.

Analysis of specific measures for quality management of auto parts

For auto parts enterprises, good quality management is not only related to product safety and service life but also an important means to improve the comprehensive competitiveness of enterprises. Therefore, the quality management of auto parts must start from the following four aspects:

1. Attach importance to the control of physical quality and implement the whole process of inspection of products.

The physical quality of auto parts is the key to whole quality control. If the physical quality cannot meet customers’ requirements, all the quality systems and objectives are meaningless. Therefore, in the process of auto parts quality management, the quality control of material objects should be taken as the key content. Mainly from the point of strengthening product inspection and improving the overall quality of products. At present, auto parts enterprises should be based on the actual production of the product, the product.

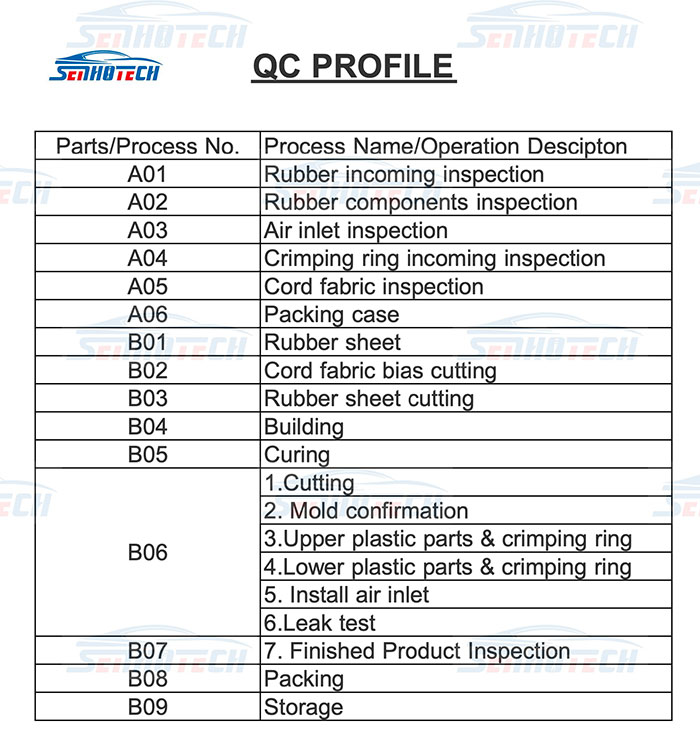

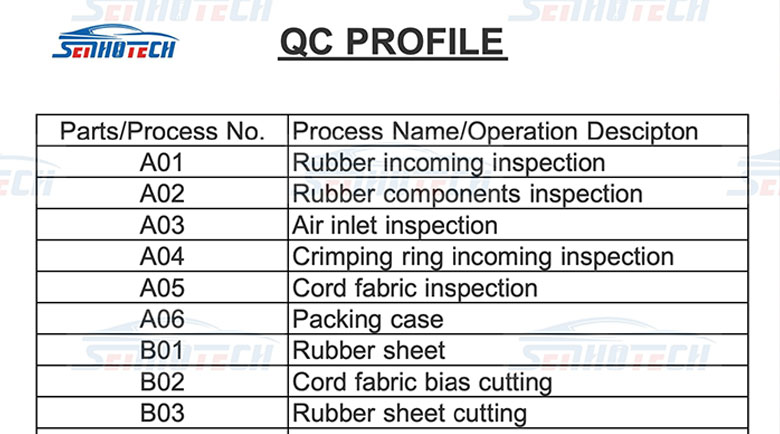

Carry out the whole process inspection to ensure that there are no blind spots or dead corners in the inspection and improve the product quality management effect through perfect inspection methods.

2. Set up the quality control points of auto parts and strengthen the quality inspection effect.

To ensure the final inspection effect of auto parts products, in the process of quality management, product quality control points of auto parts should be reasonably set, key processes of key components should be inspected, and the overall quality of products to ensure the standard. At the same time, we should also improve the inspection procedures, innovate inspection methods, introduce modern inspection and testing instruments, and carry out overall inspection of products to ensure that products meet all technical indicators before leaving the factory. Currently, the star inspection method has a positive role in improving the quality management effect of auto parts.

3. Focus on controlling the procurement of auto parts materials and accessories to solve the fundamental problem of product quality.

For auto parts, raw materials and parts are an important link to constitute auto parts products. Only by focusing on the quality control of raw materials and parts can the quality management of auto parts achieve positive effects. Based on this consideration, in the quality management process of auto parts, the procurement of raw materials and parts should be controlled with emphasis, the procurement procedures and quality inspection and acceptance procedures of raw materials and parts should be improved, and the procurement and inspection of raw materials and parts should be taken as an important content of the quality management of auto parts enterprises. Therefore, from the perspective of improving the quality management effect of auto parts, we should focus on controlling the procurement of auto parts and materials.

4. It is very important to establish a perfect quality management system and clear quality management objectives for auto parts.

Considering the importance of quality management, should actively establish a perfect quality star management system, mainly 1 into 1SO/1ATF16949 quality star management system, and according to the actual enterprise and user, requirements to set clear quality management objectives, promote the promotion of quality management behavior. Due to the variety and quantity of products produced by auto parts enterprises, the positions in the automobile system are not the same, so the quality management objectives are also different. Therefore, when formulating quality management objectives, auto parts enterprises should confirm according to product types and importance to ensure quality management.

The goal is realistic.